Intelgic

Overview of Intelgic

Intelgic: Automating Industrial Processes with AI-Powered Vision

Intelgic is a leading industrial automation company specializing in AI-based visual inspection and process intelligence. We design and develop custom Automated Optical Inspection (AOI) systems, seamlessly integrating machine vision, industrial optics, precision robotics, and AI-powered software. Our mission is to automate visual inspection processes and drive manufacturers toward Zero Defect Manufacturing.

What is Intelgic?

Intelgic provides next-generation quality inspection automation systems engineered to handle the complexity and variability of real-world production environments. Our solutions adapt to different materials, shapes, finishes, and industries, ensuring robust and reliable performance.

How does Intelgic work?

Intelgic’s systems use a combination of advanced technologies:

- AI-Based Visual Inspection: Detect surface and structural defects in real time, perform measurement inspections, and analyze surface smoothness. Applicable to various materials, including metals, plastics, electronics, automotive parts, medical devices, and aircraft parts.

- Industrial Counting & Tracking: Count items like pipes, bags, or components at entry/exit gates. Track product movement between warehouses and production lines using barcode/QR code reading integrated with ERP/MES systems.

- Advance Optics: Machine Vision Cameras, IP Cameras, and Mobile App-based capture, Line Scan Cameras for high-speed line inspection, and CIS modules for custom imaging solutions. Utilizes specialized lighting solutions and robotic motion systems for imaging complex parts.

- Process Monitoring: Monitors operators and machine workflows to validate SOP compliance using AI. Provides Digital Quality Certificates (DQC) for each product to aid in warranty validation.

Core Capabilities of Intelgic

Intelgic's core capabilities include:

- Defect Detection: Identifying scratches, pinholes, cracks, misalignments, and contamination.

- Counting & Identification: Counting pipes, products, PCB components, and packages.

- Measurement: Determining length, width, diameter, gap, and displacement using vision AI.

- Tracking & Label Reading: Identifying product IDs, vehicle numbers, labels, and barcodes.

- Automated Reporting: Creating custom reports with pass/fail logic and image proof.

- Cloud Dashboards: Offering real-time inspection reports, defect analytics, and digital quality certificates.

Industries Served

Intelgic serves a wide range of industries, including:

- Automotive: Complex metal and plastic part inspection.

- Medical Devices: Microscopic defect detection in sensitive products.

- Manufacturing: SOP monitoring, component verification, assembly QC.

- Metal & Alloy: Pipe/tube counting, bore inspection, sheet inspection.

- Electronics: PCB inspection, component counting, solder defect detection.

- Warehousing & Logistics: Inventory movement tracking, bag/box counting.

Why choose Intelgic?

- Custom Solutions: Engineered AOI solutions tailored to specific needs.

- Deep Expertise: Specialists in machine vision hardware and imaging physics.

- Robust Software: Scalable AI built for industrial environments.

- Seamless Integration: APIs for MES, ERP, and PLCs.

- Flexible Deployment: On-prem or cloud-based.

- End-to-End Support: Design, hardware, software, installation, and training.

Customer Testimonials

- Tyler Sumner, Founder | CEO, link-x.com: "Their offering has become an intricate roll within our day to day operations... they have saved us hours of labor daily within our data entry processes. They truly have been a game changer for us!"

- Ryan Teeples, Fintech CTO, 1-800Accountant: "We have used Intelgic to create technology and bots to automate key processes in our business that have saved thousands of man hours and allowed us to do things we never could scale."

Success Stories

- Automated Metal Parts Quality Inspection: Replaced manual inspection with AI-powered vision systems for a US-based manufacturing company.

- Large Metal Sheet Inspection Automation: Transformed cut-to-length metal sheet inspection with CIS imaging systems at a leading steel plant.

- Automotive Part Inspection Automation: Automated visual inspection of complex automotive parts for a global automotive company.

How to use Intelgic?

To get started with Intelgic, you can:

- Request a Demo: See Intelgic's solutions in action by requesting a personalized demo on their website.

- Contact Sales: Discuss your specific needs and how Intelgic can tailor a solution for you.

What is Automated Optical Inspection (AOI)?

Automated Optical Inspection (AOI) is a critical technology for quality control in manufacturing. It employs cameras and AI algorithms to automatically inspect products for defects, ensuring high standards and reducing manual labor.

How to improve warranty management with AI-powered machine vision?

Intelgic’s inspection automation platform provides complete visibility and traceability, allowing for better identification of defect origins and improved warranty processes.

Conclusion

Intelgic is revolutionizing industrial automation with its AI-powered visual inspection systems. By offering custom solutions, deep expertise, and robust software, Intelgic enables manufacturers to achieve zero defect manufacturing and significant operational efficiencies. Whether it's microscopic defect detection or large-scale inventory tracking, Intelgic's innovative solutions are transforming industries and driving them towards a smarter, more efficient future.

Ready to automate your quality control? Explore Intelgic's solutions and request a demo today!

AI Task and Project Management AI Document Summarization and Reading AI Smart Search AI Data Analysis Automated Workflow

Best Alternative Tools to "Intelgic"

Averroes: AI visual inspection software for 99%+ accuracy and near-zero false positives. A no-code platform for seamless, automated visual inspection and virtual metrology.

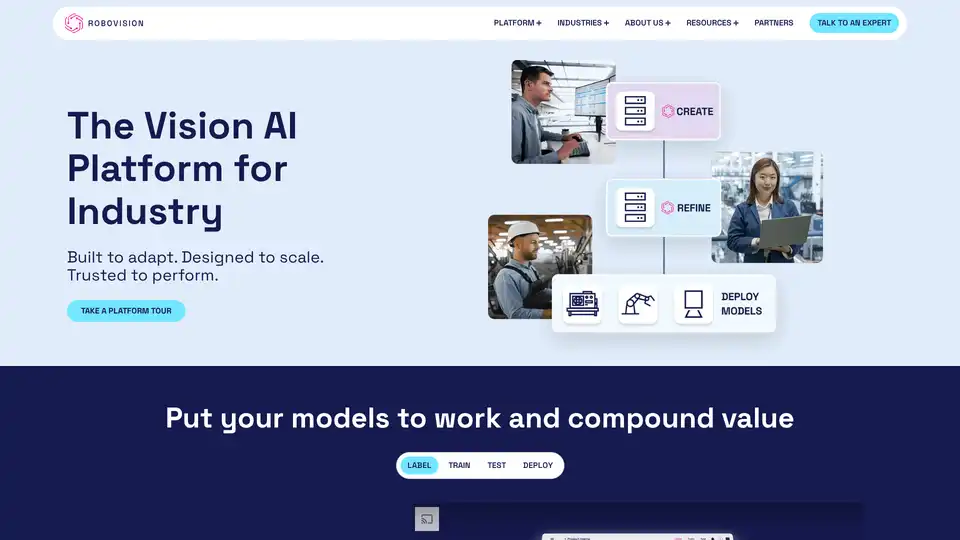

Robovision is a vision AI platform for industry, designed to adapt and scale, offering solutions for labeling, training, testing, and deploying AI models.

Discover Robovision's AI-powered computer vision platform for intelligent automation. It processes visual data with deep learning, enabling efficient model training and deployment for industries like manufacturing and agriculture.

BasicAI offers a leading data annotation platform and professional labeling services for AI/ML models, trusted by thousands in AV, ADAS, and Smart City applications. With 7+ years of expertise, it ensures high-quality, efficient data solutions.